Quality Laboratory

SOM FASTENER CO. laboratory is developed depending on customer demands and Main Principles of Laboratory Accreditation ISO/IEC 17025. Our quality and test activities with the following equipment in our laboratory continue.

PULLING TEST DEVICE:

Proof Load Test:

It is tension of applied load that the material can carry in order not to be exposed permanent change of material.

It is applied with frequencies in accordance with customer specifications (FIAT AUTO 9.52605/1, FORD WE

952, RENAULT 39-02-202) or ISO standards (ISO 898/2 & 898/6)

Nut Expanding Test:

It is applied for control of cracks or splits

that can be aroused during operation of the product.

CUTTING DEVICE

It is used in cutting of materials to prepare metallographic sample

for microscopic examinations and hardness measurement.

SANDING AND SURFACE POLISHING DEVICE

It is used for sanding and polishing among the techniques of metallographic sample preparing to ensure that the structure is seen more clearly in microscopic examinations and hardness measurement. In order to ease the polishing process, first coarse and fine sanding processes are carried out. Sanding process is mechanically ripping material from the surface of the sample. (Sandpapers of 320-600-800-1000-1200 mesh are used).

Polishing process is made by using abrasive particles with tapering sizes /6 micron and 9 micron diamond paste) in order to remove the surface roughness as the result of sanding.

DEVICE OF BAKALITE

It is used for bakalite taking for smooth sanding (parallel to the ground)

of small sized and easy-wearing samples on which metallographic examination

shall be made, placing it on microscope and making hardness measurement.

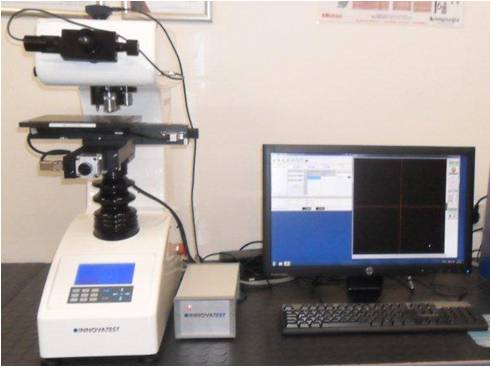

HARDNESS TEST DEVICE

It is the resistance of material to be scratched or

penetrated (permanently changes etc.) by a harder material.

Vickers (HV), Briness (HRB) and Rockwell (HRC)

hardness measurement methods are used.

METAL MICROSCOPE

It is used for examination raw materials and interior structures

of products prepared in compliance with the method of sample preparing.

It can make control with 100X, 250X, 400X and 1000X zooming.

With metal microscope, various structures of phases in the sample

such as characteristics, spread, grain boundaries, porosity, marks and cracks are examined.

PERTOMETER DEVICE

It is used in physical measurements of characteristics on which sensitive measurement must be made (angle, radius, jet diameter, countersink diameter, jet height etc.)

Sensitive measurement is carried out with device’s ability to zoom at micron level.

MACROSCOPE

It is used in examination of structural changes and various macro faults (cracking, pores, laps, slag remains etc.) occurred by the manufacturing method (regions of heat effect, directions, layers).

Examination is made with zooming 10X, 15X, 20X, 30X and 40X.

TORQUE METER

It is used in control of squeezing and dismantling torques of intrinsically safe lock nuts, fibered nuts and metal-inserted nuts.

Control is carried out depending on customer demands and in compliance with ISO 2320, WE 950 (FORD), 52605.04 (TOFAŞ/FIAT), 39-02-207 (RENAULT).

There are totally 3 torque meters.

SURFACE ROUGHNESS MEASUREMENT DEVICE

It is used to control surface roughness in measurement of product and kits.

PROFILE PROJECTOR

2D sensitive measurements of parts produced or products from

suppliers are carried out with profile projector by 10X zooming

DIGITAL MICROMETER

It is used in measurement of outer diameter in products and kits.

FLEXURE-ROLLING MEASUREMENT DEVICE

It is used to control jag flexure or rolling value in jag of nuts.

HEIGHT COMPARATOR

It is used for vertical distance measurements (source jet height, rabbet height etc.)

FIBER VIBRATION DEVICE

We use the device that we have produced as SOM FASTENER CO. in measurement loosening test of fibered nuts with torque on lot-basis in compliance with customer specifications.

Control is carried out in accordance with ISO 898-7, FIAT AUTO 9.52605.04.

MEASUREMENT STATIONS

OUR MEASUREMENT STATION IN WHICH OUR OPERATORS CONDUCT FIRST APPROVAL AND INTERLUDE CONTROL MEASUREMENTS