Tooling House

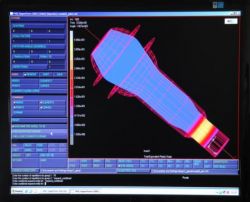

Using high end tooling production equipments in all respects, SOM Fastener manufactures 85% portion of the tooling in-house. Capable of processing difficult components, the company is well known as a challenging cold forming manufacturer.

Form stock and performance is monitored systematically by the “ERP Corporate Resource Management” software. Tooling stock traceability is achieved for approx. 350 product types. Products identified as low performance are subjected to optimization process upon review by the R&D department. As a founding member of “Metal Perfection Center” at the Atılım University, the company contributes a great deal in;

- The supply of knowledge based manufacturing technology,

- Value added product manufacture,

- Manufacture with new and advanced materials,

- Increased performance,

- Mini and micro scale product development,

- Scientific research programs on fast product development and;

- Making available of its tooling house and quality labs to the students who conduct academic studies in this specific field.

With its continuously improving and innovative structure in tooling design and in the awareness of specialized workforce as its most important asset, SOM Fastener provides its employees with permanent local and overseas training opportunities that ensure closer traceability of the worldwide improvements in its field of specialty.